Preparing to run Inventory Tracking & Job Costing Setup Wizard

❑Notifying the MKMS application that your Company will be implementing the Job Costing and Inventory Tracking System is accomplished by running the "Setup Wizard"

❖By properly preparing for the Setup Wizard, the actual execution of the Setup Wizard will be a quick and easy process.

❖The setup steps are:

a)Enter Job Costing related Sale-Purchase Items (see the "Job Costing Related Sale-Purchase Items" discussion immediately below).

b)Enter Sale-Purchase Item codes for the Non-Inventory related Expenses (see the "Non-Inventoried Job Cost Categories" discussion below).

c)Enter Job Types and the Employee records as required for Job Costing (see the "Other Job Costing Start-up Entries" discussion below).

d)Finally, run the Inventory Tracking and Job Costing Setup Wizard (see the "Setup Wizard for Inventory Tracking & Job Costing" discussion at the end of this chapter)

❖Note #1: Existing General Ledger System Users will have already entered specific Inventory related General Ledger Account Numbers.

❖Note #2: The Inventory Valuation Methodology For those Companies using the STARK 35 version of the General Ledger System, the required Inventory Valuation method is Average Cost of Inventory

Job Costing Related Sale-Purchase Items

❑Job Costing considerations: Prior to using this setup wizard you should predefine some entries based on your Company's preferences and business needs.

•These are the Sale-Purchase Item updates are required to accommodate certain Subscriber Invoicing and Vendor Purchase Order and/or Billing requirements associated with Job Costing:

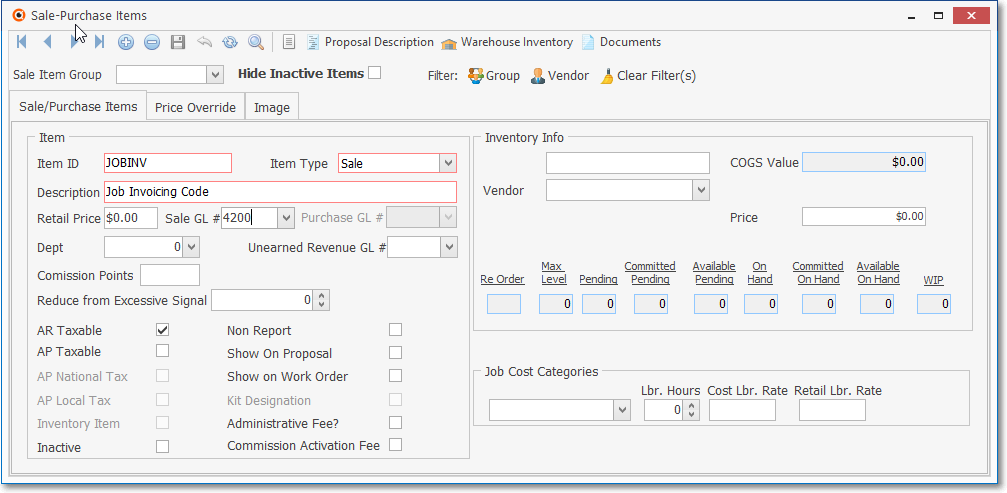

✓Enter a Sale-Purchase code of "JOBINV" (or similar) with a Type of Sale, and a Description of "Job Invoicing Code", but do not assign it a Job Cost Category.

Sale-Purchase items Form - JOBINV entry

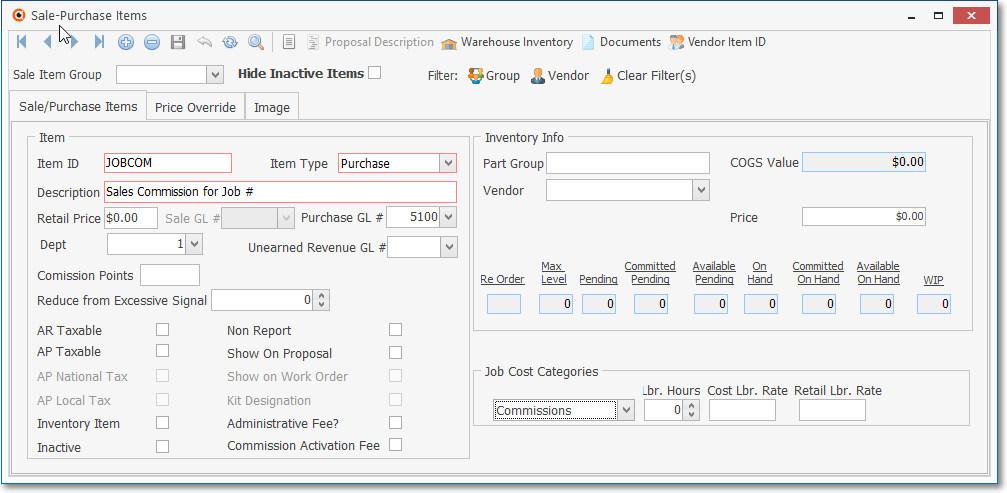

✓Enter a Sale-Purchase code of "JOBCOM" (or similar) with a Type of Purchase, and a Description of "Sales Commission for Job #:", and select the Job Cost Category of Commission.

Sale-Purchase items Form - JOBCOM entry

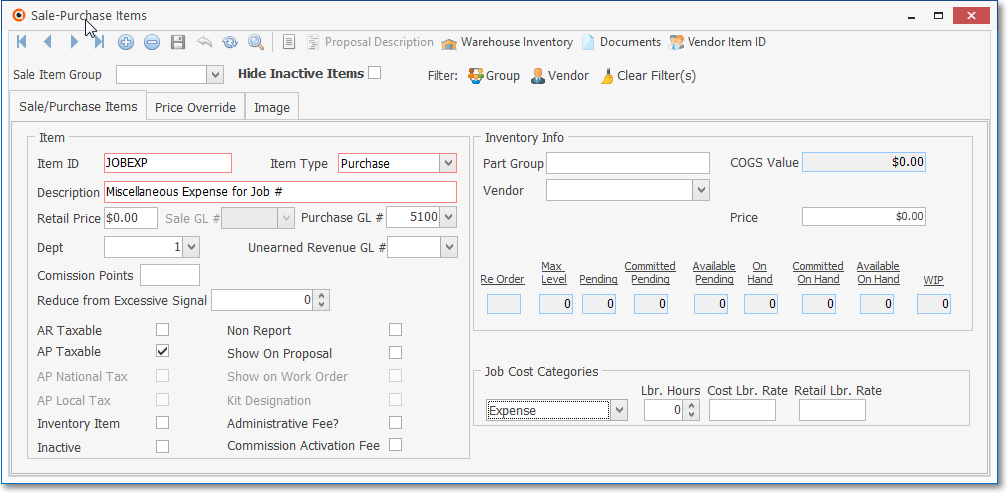

✓Enter a Sale-Purchase code of "JOBEXP" (or similar) with a Type of Purchase, a Description of "Miscellaneous Expense for Job #: ", and select the Job Cost Category of Expense.

Sale-Purchase items Form - JOBEXP entry

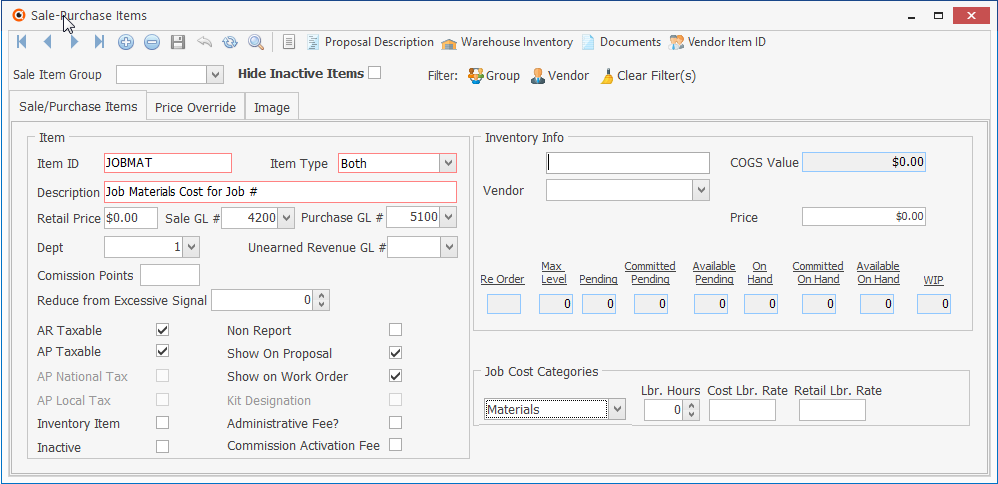

✓Enter a Sale-Purchase code of "JOBMAT" (or similar) with a Type of Both, a Description of "Job Materials Cost for Job #: ", and select the Job Cost Category of Materials.

Sale-Purchase items Form - JOBMAT entry

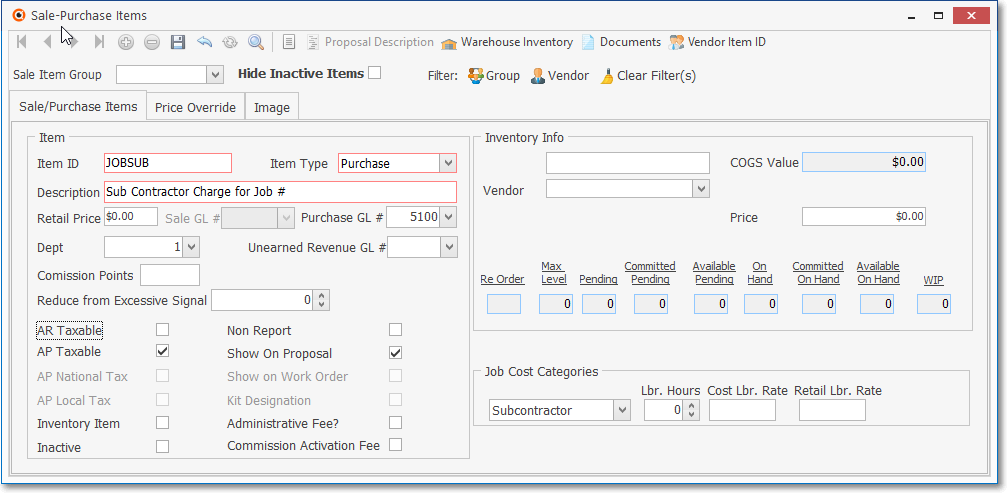

✓Enter a Sale-Purchase code of "JOBSUB" (or similar) with a Type of Purchase, a Description of "Sub Contractor Charge for Job #: ", and select the Job Cost Category of Subcontractor.

Sale-Purchase items Form - JOBSUB entry

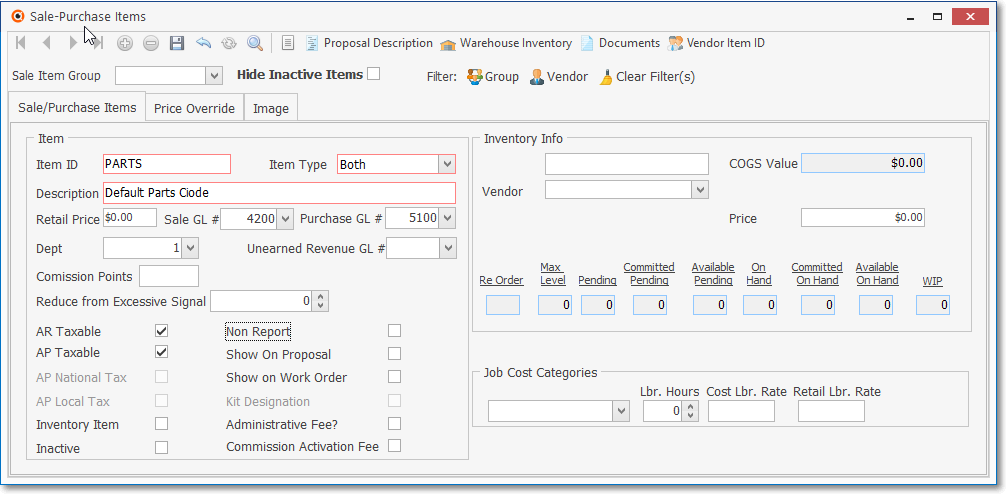

✓Enter a Sale-Purchase code for "PARTS" with a Type of Both and a Description of "Default Parts Code".

Sale-Purchase items Form - PARTS entry

Non-Inventoried Job Cost Categories

❑Later, as you Start a Job using this Inventory Tracking & Job Costing module, you will frequently need to identify Non-Inventory related Expenses for that Job.

❖To accommodate this, you should assign Job Cost Categories - and when applicable, each selected category's associated Labor related information - to each Sales-Purchase Item that may be used within the Job Costing process.

✓Sales-Purchase Items that are not Inventory Items will still be required in Job Costing to identify costs for Labor, Materials, Sub Contractor Fees various other Expenses and the Commissions for the Sale of the Job.

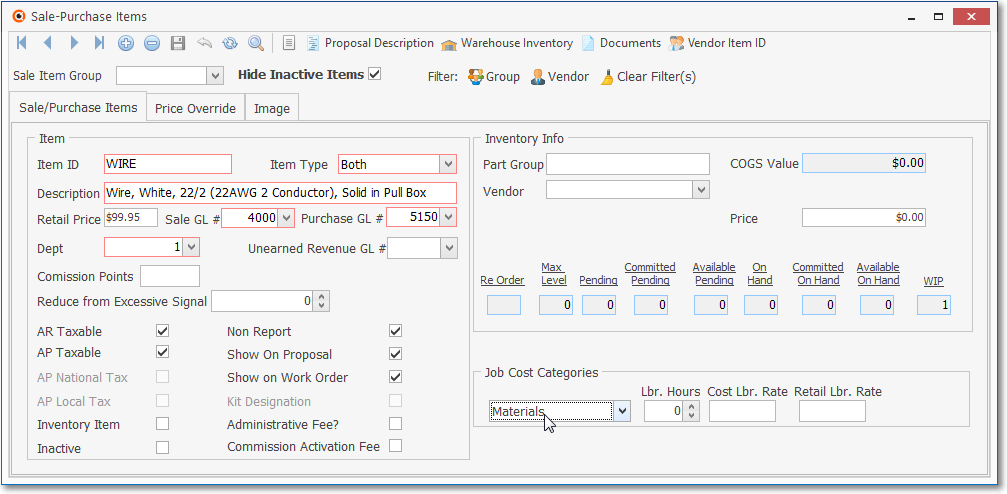

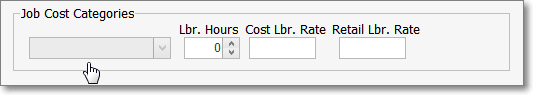

Job Cost Categories & Labor related fields on Sale-Purchase Item Form

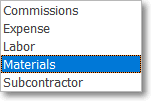

✓The Non-Inventoried Job Cost Categories are:

▪Commissions - paid to Employee Team members.

▪Expenses - costs specific to an Installation

▪Labor - if selected, enter the number of Hours and the Cost for each for this expense (see the "Labor Hours and Cost Labor Rate" discussion below).

▪Materials - for identifying lump-sum materials costs not defined as Inventory Items or as any of the other Job Cost Categories.

▪Sub-Contractors - fees paid to non-employees for the completion of a Job which would be entered as a lump-sum amount.

✓If you have not yet done so, enter the Job Cost Category for each appropriate Sales-Purchase Item likely to be used to record these types of expenses by using the Drop-Down Selection List provided.

✓The Job Cost Categories field is not available on the Sales-Purchase Item Form when defining an actual Inventory Item and/or Kit.

▪When an Inventory Item is viewed, the field to enter a Job Cost Category is Light Gray - because Inventory usage is tracked separately.

❖Labor Hours and Labor Rate - The Labor related data entry considerations on the Sales-Purchase Items Form:

✓If this Purchase Category is an Inventory Item:

▪Labor Hours - ("Lbr. Hours") - This field is used to define - when this is an Inventory Item - the average number of Labor hours required to install this specific Part.

▪Cost Labor Rate - ("Cost Lbr. Rate") - This field is used to estimate - when this is an Inventory Item - the average internal Cost for each hour required to install this specific Part.

▪Retail Labor Rate - ("Retail Lbr. Rate") - This field is used to estimate - when this is an Inventory Item - the average Retail Charge for each hour required to install this specific Part.

➢Note: If this Inventory (Sale-Purchase) Item is included in a Proposal which is subsequently converted to a Job, this Retail Labor Rate information is included in the Job Estimate tab.

✓If this Purchase Category is not an Inventory Item:

▪Labor Hours - ("Lbr. Hours") - This field is used to estimate the average number of Labor hours required for the designated Job Cost.

▪Cost Labor Rate - ("Cost Lbr. Rate") - This field is used to estimate the average internal Cost for each hour required for the designated Job Cost.

▪Retail Labor Rate - ("Retail Lbr. Rate") - This field is used to estimate the average Retail Charge for each hour required for the designated Job Cost.

Other Job Costing Start-up Entries

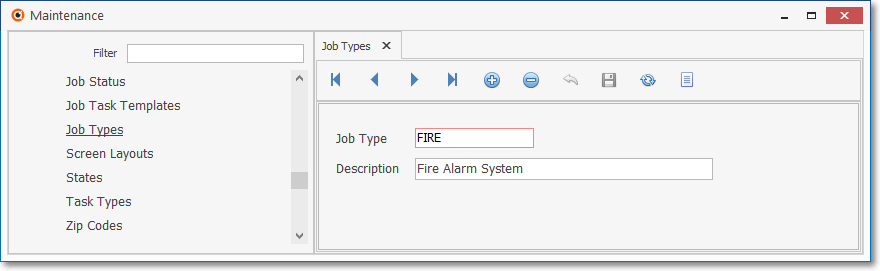

❑Enter Job Types information to establish codes for the typical types of Jobs that your Company performs.

Job Types Form

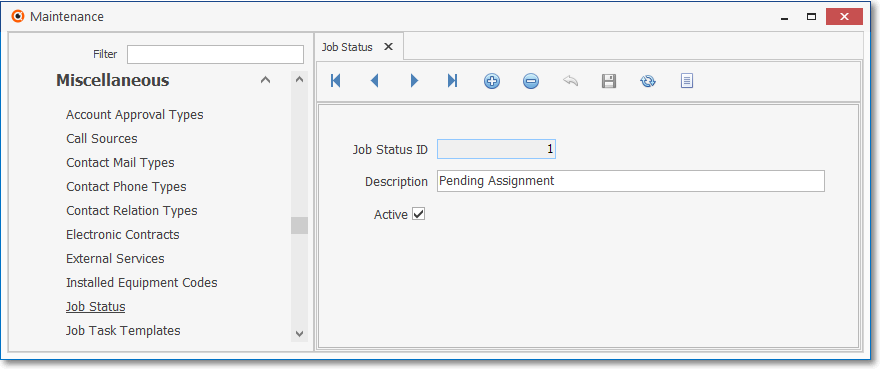

❑Enter Job Status descriptions which are used to define the Progress of Job Costing records (e.g., Status of the Job as it progresses from creation to completion)

Job Status Form

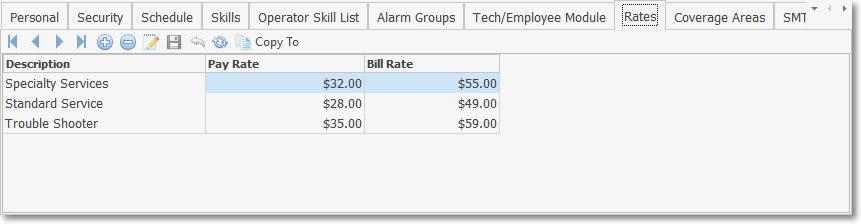

❑Within the Employee Form

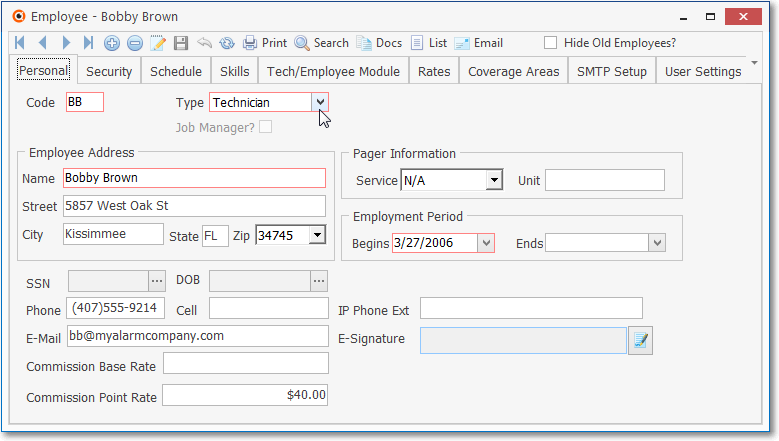

❖Enter the Pay Rates for those Employees who will work at least some of the time as a Technician, and are identified as such because they are assigned an Employee Type of Technician or All.

Employee Form - Rates tab - Employee Pay Rates entries

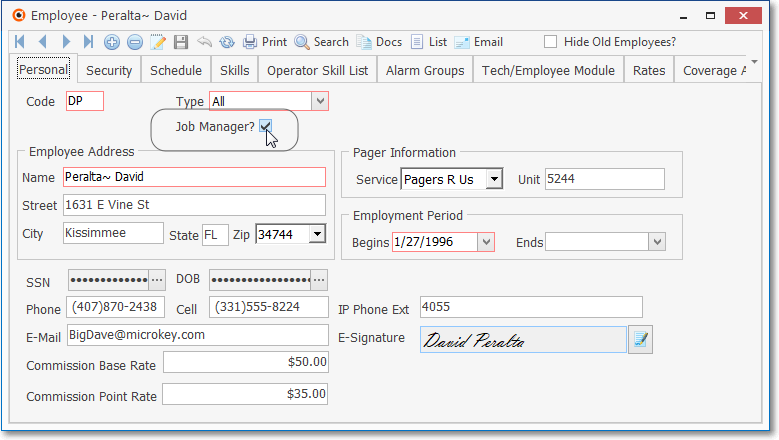

❖Identify each Employee who is to be classified as a Job Manager by Checking the Job Manager box on the Personal tab of the Employee Form.

✓To assign an Employee the rights of a Job Manager, their Employee Type field on the Personal tab must be set as either All or Administration.

Employee Form - Personal tab - Job Manager Check Box

✓Because there will be no need for it, the Job Manager? Check box will be “Grayed” out if the Operator, Sales, or Technician Type is assigned to the Employee.

Employee Form - Personal tab - Type (of Employee) field

❑There are three Inventory Valuation Methods available:

1.Original Price - The cost entered as the Price on the Sale-Purchase Items Form

2.LIFO - Last In / First Out - The cost as determined by the most recent Price that was paid for an Inventory Item as recorded on a Bill.

3.Average Inventory Cost - Automatically Recalculated Average Cost of each Inventory Item, but initially by using the Calculate Inventory Item Average procedure.

❖For those Companies using (or intend to use) the STARK 35 version of the General Ledger System, the required Inventory Valuation Method is the Average Cost of Inventory

✓The Average Inventory Cost method provides an automatic Inventory Revaluation when using the General Ledger System in conjunction with the Inventory Tracking System.

✓See the "An Analysis of the various Inventory Tracking System Processes" section in the Understanding how Inventory Values & Counts are Calculated chapter, and the Inventory Valuation Method chapter for more detailed information.

Setup Wizard for Inventory Tracking/Job Costing

❑Using the Job Costing and Inventory Tracking Setup Wizard

➢Note: If you will be using Average Cost of Inventory as your Company's Inventory Valuation Method or have previously used the Inventory Tracking and Job Costing Systems:

a)The "start-up" entries that would be executed by the setup wizard may have to be manually updated because the automated setup wizard may not be available to you.

b)These manually updated Entry Requirements may be completed as follows:

1)In the Warehouse Form verify that the Default Warehouse already exists, or create a new Warehouse record that your Company wants to use as its Default Warehouse..

2)The Divisions Form allows your Company to identify a Default Warehouse for that (each) Division

▪Thereafter, when Invoices, Purchase Orders, Bills and/or Work Orders are created for a Subscriber who was assigned to a Division (a Division assignment to a Subscriber is optional), by default, any Inventory related Transaction posted to one of those Invoice, Purchase Order, Bill and/or Work Order documents will automatically be assigned to that default Division Warehouse but may be changed when needed.

3)In the Sale-Purchase Items Form enter a Sale-Purchase code of "JOBINV" (or similar) with a Type of Sale, and a Description of "Job Invoicing Code" but do not assign it a Job Cost Category.

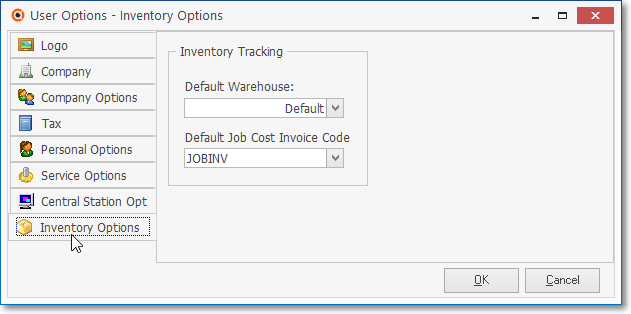

4)In the User Options Form within the Inventory Options tab,

User Options Form - Inventory Options tab

❖Important! - Before proceeding with this setup wizard, review the Inventory Valuation Method chapter to understand your Company's Inventory Valuation options.

•To run the setup wizard for Inventory Tracking and Job Costing Setup:

e)From the Backstage Menu System Select File then Select the General sub-menu, or

f)From the Quick Access Menu, Select File

✓Choose the Start Inventory Tracking/Job Costing option

![]()

Quick Access Menu - File Menu Start Inventory Tracking/Job Costing option

❑Completing the Inventory Tracking and Job Costing Setup dialog:

•The standard Inventory Valuation Method is Original Price (Cost)

❖The Inventory Valuation Methodology: For those Companies using the STARK 35 version of the General Ledger System, the required Inventory Valuation method is Average Cost of Inventory

![]()

Inventory Tracking and Job Costing Setup

•Default Warehouse - The default entry is the system's predefined Default Warehouse. However, you may define a different one to be used as your Company's Default Warehouse.

✓When entering a Detail Line Item on a Sales Invoice for the sale of an Inventory Item, or on a Bill for the Purchase of an Inventory Item, the Warehouse from which this Inventory Item was (or will be) taken (or stocked) is identified - by default - as the Default Warehouse selection provided here.

▪Use the Drop-Down Selection List to Choose a different Warehouse Name, if desired.

✓The Divisions Form allows your Company to identify a Default Warehouse for that (each) Division

▪Thereafter, when Invoices, Purchase Orders, Bills and/or Work Orders are created for a Subscriber who was assigned to a Division (a Division assignment to a Subscriber is optional), by default, any Inventory related Transaction posted to one of those Invoice, Purchase Order, Bill and/or Work Order documents will automatically be assigned to that default Division Warehouse but may be changed when needed.

•Default Job Cost Invoice Code - Enter the default Sale-Purchase Item that is to be used when creating a Job Costing Invoice.

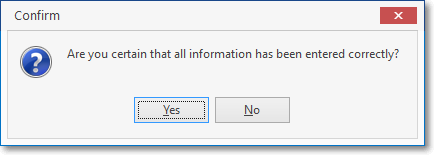

•Click the Finished button

✓Confirm that you have correctly entered the Information; or Click No to abort the entry if you need to start over.

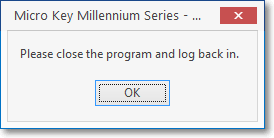

Please reboot the program and log back in.

❖Close the MKMS application, then restart it to activate the Job Costing and Inventory Tracking System.

❑Selecting the appropriate Inventory Valuation Method - There are several Inventory Valuation Method to be considered:

•By default, Inventory Items are Valued based on the Price that was entered for each Inventory Item in the Sale-Purchase Items Form when they were defined. This is referred to as the Original Price (Cost) method.

•Consider these available Inventory Valuation Methods:

➢Average Cost of Inventory - For those Companies using the STARK 35 version of the General Ledger System, the required Inventory Valuation method is Average Cost of Inventory

▪The system calculates and maintains the Average Purchase Price of the Inventory Items which are currently "in stock"

▪Read the Inventory Valuation Method chapter to fully understand the implementation of this option.

▪Then, once the setup wizard is completed, follow the process described in the Average Cost of Inventory discussion within the Inventory Valuation Methods chapter to reset the AverageCostInventory option to True ("T") in the Company Settings dialog.

✓Original Price (Cost) - If you are using a version of MKMS that is older than 5.1.34.XXXX and you want (for whatever crazy reason) to use the Original Price method:

oBy default, new Purchases do not change the Price which the Inventory Tracking System uses to Value that Inventory Item.

oSo, the Inventory Item continues to be valued based on the Original Price entered (or as subsequently modified manually) in the Sales-Purchase Items Form.

✓LIFO (Last In - First Out) - From time to time, Inventory Items may be Purchased for more, or less, than what was originally entered on the Sale-Purchase Item Form in the Price field.

▪To set the LIFO box to initiate this (Last In - First Out) Inventory Valuation Method, set the LIFO option to True ("T") in the Company Settings dialog - accessible from within the Company tab of the User Options Form.

▪From an accounting standpoint, your Company will almost certainly want to alter the default Original Price behavior by having that Price Value reset, based on the most recent Cost recorded on a Bill for the Purchase of an Inventory Item.

➢Note: For those Companies using (or who intend to use) the STARK 35 version of the General Ledger System, the required Inventory Valuation method is Average Cost of Inventory

▪Do not use LIFO

▪If LIFO had been used previously, be sure to set the LIFO option to False ("F") in the Company Settings dialog, then follow the instructions described in the Average Cost of Inventory discussion within the Inventory Valuation Methods chapter to reset the AverageCostInventory option to True ("T") in that Company Settings dialog - thus "turning on" the Average Cost of Inventory valuation method.

❑Additional Steps you may want to perform:

❖Information you've entered through the setup wizard may be reset within this Inventory Options tab on the User Options Form.

❖Consider creating User Defined Kits to speed the Ordering Inventory Items, and Invoicing for the Purchase of those Inventory Items.

❑What's Next?

❖Read Inventory Options.

❖Enter your Job Types and Warehouse locations.